We'are Open: Mon - Sat 10:00 AM - 7:00 PM

We'are Open: Mon - Sat 10:00 AM - 7:00 PM We'are Open: Mon - Sat 10:00 AM - 7:00 PM

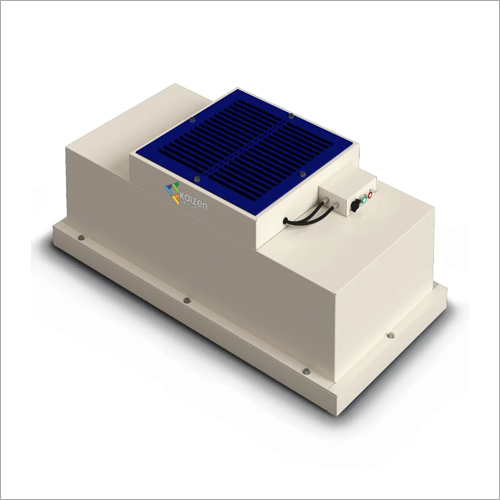

We'are Open: Mon - Sat 10:00 AM - 7:00 PMClean Booth

Price 1330000 INR/ Square Meter

Clean Booth Specification

- Power Consumption

- 0.25 KW

- Floor

- Epoxy Coated GI or SS Chequered Plate

- Weight

- 180 kg

- Type

- Modular Clean Booth

- Voltage

- 220 V

- Application

- Pharmaceutical, Research labs, Electronics, Hospitals

- Door

- PVC Strip or Hinged Door

- Lighting

- LED Light Fittings

- Thickness

- 1.2 mm (Panel Thickness)

- Filter Type

- HEPA (99.99% 0.3 micron), Pre-Filter

- Feature

- Portable, Modular construction, Easy installation

- Filters

- HEPA & Pre Filter Set

- Material

- GI Powder Coated / Stainless Steel

- Condition

- New

- Dimension (L*W*H)

- 2400 mm x 1500 mm x 2200 mm

- Air Flow

- Vertical Laminar Flow

- Air Volume

- 1200 CFM

- Frame Material

- Anodized Aluminium / Stainless Steel

- Installation Site

- Indoor only

- Relative Humidity

- Less than 70%

- Frequency

- 50 Hz

- Mobility

- Mounted on Castor Wheels

- Noise Level

- Less than 65 dB(A)

- Cleanliness Class

- Class 100 / ISO 5

- Color

- Off White/Custom

- Panel Type

- Sandwich Panel

Clean Booth Trade Information

- Minimum Order Quantity

- 50 Square Meters

- Supply Ability

- 15 Square Meters Per Day

- Delivery Time

- 15 Days

About Clean Booth

We are supplying a unique range of Clean Booth. It is counted as a best choice for clean room. This booth is applicable to pharmaceutical and biochemical industries. It is a controlled environment where pollutants like dust and other harmful microbes are easily filtered out. Clean Booth is used for manufacturing products such as medical equipment, electronic devices and so on. It is a booth which maintains a specific level of air particles.

Specification

| Feature | Gasketed lens cover |

| Finish | Powder Coated |

| Frame Material | MS |

| Light Fixture | 2'x2' and 2'x4' |

| Height | 2.5 meter |

| Material | MS or SS |

| Brand | Kaizen |

| Noise | 60 DB |

| Door Finishing | Powder Coated |

| Frequency | 50 Hz |

| Voltage | 220 V |

Reliable Class 100 Cleanliness

Maintain a contamination-free workspace with a certified Class 100 / ISO 5 modular clean booth. Its robust air filtration system, including HEPA and pre-filter sets, traps 99.99% of particles down to 0.3 microns, supporting strict ISO compliance for sensitive work environments.

Mobility Meets Convenience

Effortlessly relocate your clean booth thanks to industrial-grade castor wheels. Designed for flexibility in layout and workflow, the portable booth suits evolving needs in laboratories, hospitals, and production areas. Fast setup and modular construction ensure seamless integration indoors.

Durable Build and Custom Options

Constructed with a 1.2 mm thick sandwich panel, available in off-white or custom colors, this booth combines aesthetics and strength. Epoxy-coated GI or stainless steel floors and anodized aluminium framing further guarantee structural integrity and easy cleaning.

FAQ's of Clean Booth:

Q: How is the Modular Clean Booth installed at an indoor site?

A: The clean booth features easy-to-assemble modular panels and can be quickly set up at any indoor location. Its lightweight design and castor wheels allow for effortless positioning and installation without complex construction requirements.Q: What filtration system is used to maintain Class 100 / ISO 5 standards?

A: The booth utilizes a vertical laminar airflow system powered by HEPA filters that capture 99.99% of particles as small as 0.3 microns, combined with pre-filter sets. This ensures ultra-clean air and reliable performance in critical environments.Q: When should I use a clean booth in my facility?

A: The modular clean booth is ideal for any process requiring stringent contamination control, such as pharmaceutical manufacturing, electronics assembly, medical research, and hospital procedures. Use it when a certified Class 100 / ISO 5 environment is essential.Q: Where is this clean booth suitable for installation?

A: Designed for indoor use only, the clean booth fits seamlessly into laboratories, hospital cleanrooms, research settings, and other controlled environments needing low noise and strict air purification.Q: What benefits do the mobility and modular design offer?

A: Mobility via castor wheels provides flexible positioning, making it easy to adapt the booth layout to evolving operational needs. Modular construction allows for fast setup, easy relocation, and potential expansion or reconfiguration.Q: How does the clean booth ensure user safety and comfort?

A: The booth operates at less than 65 dB(A) for low noise, features LED lighting for clear visibility, and maintains comfortable conditions with humidity below 70%. Its energy-efficient system also reduces operational costs.Q: What materials are used for durability and hygiene in the clean booth?

A: The clean booth is constructed from GI powder coated or stainless steel panels and anodized aluminium or stainless steel frames. The epoxy-coated GI or stainless steel chequered plate floor simplifies cleaning and resists chemicals, ensuring longevity and hygiene.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Clean Room Equipment Category

Clean Room Cabinet

Price 120000 INR / Unit

Minimum Order Quantity : 50 Square Meters

Floor : Perforated Stainless Steel

Power Consumption : 220 W

Application : Pharmaceutical, Laboratory, and Electronics Clean Rooms

Door : Acrylic/Polycarbonate Transparent Door with SS Frame

Horizontal Laminar Workstation

Price 175000 INR / Unit

Minimum Order Quantity : 1 Number

Floor : Flat Stainless Steel Work Surface

Power Consumption : 250 Watt

Application : Laboratory, Pharmaceutical, Electronic Assembly, Research

Door : Front Sliding Acrylic Door

Static Pass Box

Price 175000 INR / Unit

Minimum Order Quantity : 1 Number

Floor : Same as enclosure material/Stainless Steel tray

Power Consumption : Negligible (Static unit)

Application : Transfer of materials between clean and nonclean areas

Door : Double leaf hinged doors with glass view panel and electromagnetic interlock

Send Inquiry

Send Inquiry

Call Me Free

Call Me Free

English

English Spanish

Spanish French

French German

German Italian

Italian Chinese (Simplified)

Chinese (Simplified) Japanese

Japanese Korean

Korean Arabic

Arabic Portuguese

Portuguese