We'are Open: Mon - Sat 10:00 AM - 7:00 PM

We'are Open: Mon - Sat 10:00 AM - 7:00 PM We'are Open: Mon - Sat 10:00 AM - 7:00 PM

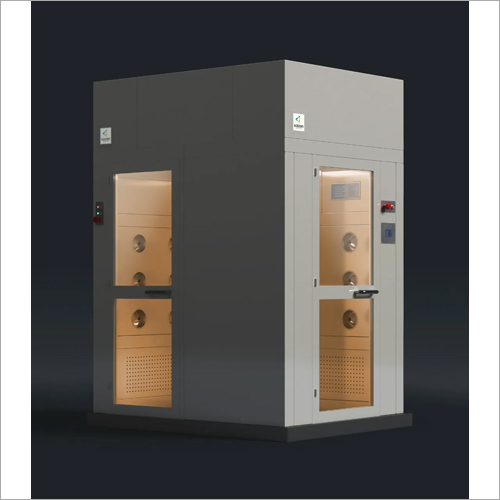

We'are Open: Mon - Sat 10:00 AM - 7:00 PMCleanroom Air Shower

Price 175000 INR/ Unit

Cleanroom Air Shower Specification

- Feature

- Microprocessor-based control panel, touch-free sensor

- Frame Material

- Stainless Steel

- Power Consumption

- 750 W

- Condition

- New

- Floor

- Stainless Steel with anti-slip mat

- Dimension (L*W*H)

- 1200 x 1000 x 2000 mm

- Voltage

- 230 V AC

- Nozzle

- Stainless Steel Rotating Nozzle

- Material

- Stainless Steel / Mild Steel with powder coating

- Door

- Automatic (interlocked), both sides

- Lighting

- LED light

- Air Flow

- 25 m/s-28 m/s

- Thickness

- 1.2 mm

- Filter Type

- HEPA (High Efficiency Particulate Air)

- Weight

- Approx. 250 kg

- Filters

- Pre-Filter & HEPA Filter

- Air Volume

- 1000-1200 m/hr

- Type

- Air Shower

- Application

- Cleanroom entry and exit

- Noise Level

- < 70 dB

- Service Access

- Removable side panels for maintenance

- Safety Feature

- Emergency stop button

- Finish

- Matte/Glossy, as per requirement

- Installation

- Freestanding, plug-and-play

- Cabin Illumination

- Bright internal lighting for visibility

- Door Interlocking

- Electronic interlock system to prevent simultaneous opening

- Blower Motor

- Heavy-duty, low-noise centrifugal

- Usage

- Pharmaceutical, Biotechnology, Hospitals, Food Processing

- Number of Nozzles

- 12 (6 on each side)

- Operating Time

- 0-99 seconds adjustable

- User Capacity

- 1-2 persons per cycle

- Panel Display

- Digital display panel for settings

Cleanroom Air Shower Trade Information

- Minimum Order Quantity

- 1 Number

- Supply Ability

- 15 Per Day

- Delivery Time

- 15 Days

- Main Domestic Market

- All India

About Cleanroom Air Shower

Kaizen Air Shower is often used in conjunction with clean room. To manufacture this shower, we use best quality stainless steel. It filter through the action of high strength air flow. Equipped with airlock function to control the moving in & out behavior of operators effectively. It is manufactured using pristine grade components and sophisticated techniques by our experts. Offered Kaizen Air Shower is easy to install and require less maintenance.

Specification

| Air Shower Velocity | 20 - 22(m/s) /3.937 - 4.330(fpm) ownword |

| External Dimensions | 1500 x 1000 x 2600 mm |

| Internal Dimensions | 950 x 900 x 1950 mm |

| Model | KAS-H6 |

| Voltage | 220-240 VAC |

| Height | 2600 mm |

| Air Flow | 1500 CFM |

| Material | Powder coated or SS |

| Brand | Kaizen |

| Corrosion Resistance | Yes |

| Frequency | 50 Hz |

| Usage/Application | Industrial |

Superior Air Filtration for Cleanrooms

Equipped with both pre-filter and HEPA filter technology, this air shower provides highly effective particulate removal, ensuring cleanroom integrity. With air velocities of 2528 m/s and a powerful blower motor, contaminants are dislodged efficiently from personnel entering or exiting sensitive environments.

User Safety and Convenience

The system incorporates electronic door interlocking to prevent simultaneous opening, an emergency stop button for rapid response, and a microprocessor-based touch-free control panel. Internal LED illumination ensures visibility for up to two users, and removable side panels offer accessible maintenance.

FAQs of Cleanroom Air Shower:

Q: How does the Cleanroom Air Shower enhance contamination control?

A: The air shower uses 12 high-velocity stainless steel rotating nozzles and HEPA filtration to remove dust and particulate contaminants efficiently from personnel, providing a clean environment before entering or exiting cleanroom facilities.Q: What type of industries can benefit from installing this Cleanroom Air Shower?

A: Industries such as pharmaceuticals, biotechnology, hospitals, food processing, and any facility requiring contamination control will benefit from the reliability and high performance of this unit.Q: When should the Cleanroom Air Shower be used in daily operations?

A: It should be used whenever individuals enter or exit a cleanroom to prevent cross-contamination, particularly during shift changes or before accessing sensitive areas.Q: Where is the optimal location for installing this air shower?

A: The air shower should be installed at all entry and exit points to cleanrooms or critical controlled areas. Its freestanding, plug-and-play design makes placement flexible and straightforward.Q: What is the process for operating the Cleanroom Air Shower?

A: Users simply enter the cabin, where the automatic interlocked doors secure them. The touch-free sensor is engaged, activating the high-speed nozzles for an adjustable cycle, and HEPA-filtered air dislodges and removes contaminants before exit.Q: What maintenance procedures are supported by the unit?

A: Removable side panels provide easy access for servicing filters, blower motor, and other internal components, ensuring efficient upkeep and minimizing downtime.Q: What are the key benefits of using this Cleanroom Air Shower?

A: Key benefits include advanced particulate removal, energy-efficient operation (750 W), safety features, rapid cycle times, and compliance with cleanroom standards, thus protecting sensitive environments and ensuring operational continuity.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

Send Inquiry

Send Inquiry

Call Me Free

Call Me Free

English

English Spanish

Spanish French

French German

German Italian

Italian Chinese (Simplified)

Chinese (Simplified) Japanese

Japanese Korean

Korean Arabic

Arabic Portuguese

Portuguese