We'are Open: Mon - Sat 10:00 AM - 7:00 PM

We'are Open: Mon - Sat 10:00 AM - 7:00 PM We'are Open: Mon - Sat 10:00 AM - 7:00 PM

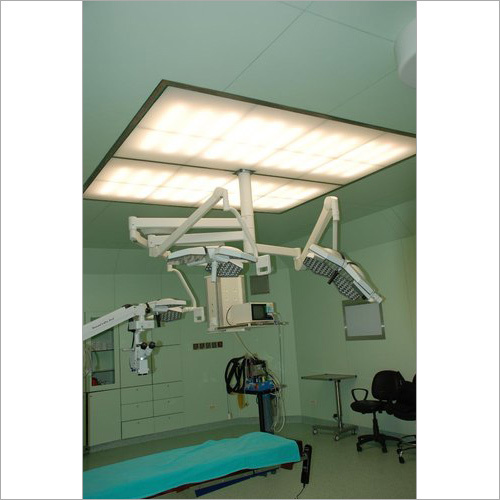

We'are Open: Mon - Sat 10:00 AM - 7:00 PMLaminar Flow Operating Theatre

Price 125000 INR/ Unit

Laminar Flow Operating Theatre Specification

- Insulation

- PUF / Mineral Wool

- Life Span

- 15-25 Years

- Open Style

- Sliding / Hinged

- Connection

- Modular - Panel to Panel Interlocking

- Dimension (L*W*H)

- Customizable (Typical: 6m x 6m x 3m)

- Window Material

- Double Glazed Toughened Glass

- Wall Materials

- Powder Coated GI Panel

- Door Material

- Powder Coated Steel or SS Door

- Material

- Galvanized Steel, Stainless Steel

- Roof Material

- GI Sheet with Insulation

- Door

- Hermetically Sealed Auto / Manual Doors

- Thickness Of Wall Panel

- 50 mm / 80 mm

- Window

- Laminated Toughened Glass

- Window Style

- Fixed Flush Glazed

- Floor Material

- Epoxy Antistatic Vinyl

- Floor Load

- 250 kg/m2

- Roof Dead Load

- 40 kg/m2

- Roof Live Load

- 150 kg/m2

- Earthquake Intensity

- Seismic Resistance up to Zone IV

- Color

- White / Blue (As per requirement)

- Use

- Medical Operation / Surgical Room

- Noise Level

- Below 60 dB(A)

- Cleanliness Standard

- Class 100 to 1000 (ISO 5 to ISO 6)

- Illumination Level

- 300 Lux

- Temperature Range

- 20C 24C (Adjustable)

- Air Change/Hour

- 25 60 per hour

- Power Supply

- 220/240V 50Hz, Single/3 Phase

- Relative Humidity

- 50-60% (Adjustable)

- Panel Joint Sealing

- Silicone / Antimicrobial Sealant

- Air Handling Unit

- Double Skin with 3 stage filtration

- Control System

- Microprocessor Based Control Panel

- Return Air

- Low Level Modular Return Air Grille

- Lighting

- Recessed LED / Shadowless Lamps

- HEPA Filtration Efficiency

- 99.99% at 0.3 Microns

- Pressure Differential

- 15-20 Pa positive pressure

- Air Velocity

- 0.3 0.5 m/s at Grille Level

- Finish

- Antimicrobial Powder Coated

Laminar Flow Operating Theatre Trade Information

- Minimum Order Quantity

- 50 Square Meters

- Supply Ability

- 15 Square Meters Per Day

- Delivery Time

- 15 Days

About Laminar Flow Operating Theatre

We are providing a wide array of Laminar Flow Operating Theatre. It is used to keep the air clean of dust and microorganisms. Therefore, provided theatre is contributing to the improvement of Hospital areas and reducing the risk of infection by designing. It creates an extremely homogeneous laminar flow with very little turbulence. Laminar Flow Operating Theatre is effectively used to reduce the number of infective organisms in the theatre air. It is easy to maintain for longer years.

Specification

| Noise level | 60dB |

| Particle retention | 0.3 micron |

| Velocity | 90FPM |

| Brand | Kaizen |

| Material | Steel |

| Built Type | Modular |

| Usage/Application | Hospital |

Advanced Air Filtration and Control

This operating theatre integrates a three-stage filtration system, including HEPA filters with 99.99% efficiency at 0.3 microns. Microprocessor-based controls maintain air velocity (0.30.5 m/s), 1520 Pa positive pressure, and 2560 air changes per hour. The system ensures a consistent, sterile environment essential for infection prevention in critical surgeries.

Optimized Lighting and Ergonomics

Equipped with energy-efficient recessed LED and shadowless lamps, the theatre achieves illumination levels above 300 Lux. The ergonomic design, complete with customizable dimensions and modular interlocking construction, facilitates seamless workflow, promoting medical precision and maintaining a contaminant-free atmosphere.

Durable and Hygienic Construction

Constructed with powder-coated GI panels, hermetically sealed doors, and toughened double-glazed glass, the theatre offers a clean, durable, and low-maintenance environment. The use of antimicrobial sealing materials and epoxy antistatic vinyl flooring further enhances hygiene and safety standards, crucial for any surgical facility.

FAQs of Laminar Flow Operating Theatre:

Q: How does the HEPA filtration ensure a sterile environment in the operating theatre?

A: HEPA filtration captures 99.99% of airborne particles down to 0.3 microns, drastically reducing the risk of airborne contamination. Combined with 2560 air changes per hour and a double-skin air handling system, this setup maintains ISO Class 1001000 cleanliness, safeguarding both patients and medical personnel during procedures.Q: What benefits does the microprocessor-based control panel offer for surgical operations?

A: The microprocessor-based control panel allows precise regulation of air velocity, temperature (20C24C), humidity (5060%), and pressure differential (1520 Pa). This ensures the environment remains optimal for surgeries, offering responsive adjustments as needed and consistently meeting stringent medical standards.Q: When should the operating theatres air filters be serviced or replaced?

A: Filter replacement schedules depend on usage and local air quality, but typically, prefilters are checked every 36 months, with HEPA filters requiring inspection or replacement every 1224 months. Regular maintenance by qualified professionals is advised to uphold desired air quality and operational safety.Q: Where can this modular operating theatre be installed?

A: The theatre is designed for flexibility and can be installed in hospitals, specialty clinics, or medical centers. Its modular, customizable nature allows easy assembly in new constructions or within existing hospital structures, adjusting to space and layout requirements.Q: What process is followed for installing the laminar flow operating theatre?

A: Installation involves site assessment, customization of size and specifications, delivery of prefabricated modular panels, and on-site assembly. Skilled technicians manage integration of electrical, HVAC, and control systems, ensuring reliability, compliance with standards, and rapid deployment.Q: How is user comfort and safety ensured during surgical procedures?

A: With noise maintained below 60 dB(A), bright 300+ Lux shadowless lighting, positive air pressure, and consistent temperature and humidity control, the theatre guarantees a comfortable, safe environment. Antimicrobial coatings and seamless finishes further enhance patient and staff protection from infection.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Modular Operation Theatre Category

Kaizen Modular Operation Theatre

Price 145000.00 INR / Unit

Minimum Order Quantity : 50 Square Meters

Wall Materials : Other, Insulated modular panels with powder coated GI sheet

Color : White and blue (customizable as required)

Window Style : Other, Fixed glaze, flush mounted

Door Material : Other, Hermetically sealed stainless steel or powder coated GI

Prefabricated Operation Theatre

Price 105000 INR / Unit

Minimum Order Quantity : 50 Square Meters

Wall Materials : Other, Jointless PUF panel, GI precoated/SS laminated finish

Color : White, customizable options

Window Style : Other, Fixed, optional with Venetian blinds

Door Material : Other, Powdercoated galvanized steel, Hermetically sealing

Send Inquiry

Send Inquiry

Call Me Free

Call Me Free

English

English Spanish

Spanish French

French German

German Italian

Italian Chinese (Simplified)

Chinese (Simplified) Japanese

Japanese Korean

Korean Arabic

Arabic Portuguese

Portuguese