We'are Open: Mon - Sat 10:00 AM - 7:00 PM

We'are Open: Mon - Sat 10:00 AM - 7:00 PM We'are Open: Mon - Sat 10:00 AM - 7:00 PM

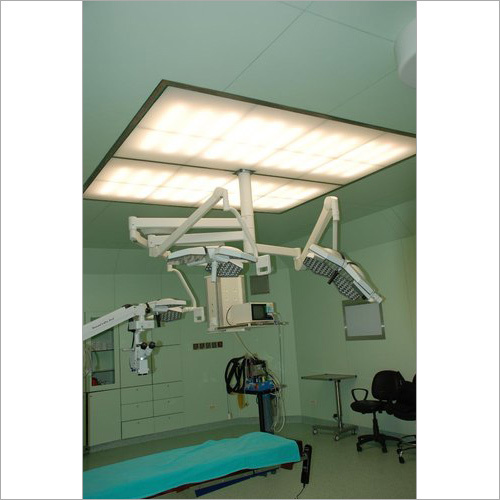

We'are Open: Mon - Sat 10:00 AM - 7:00 PMPrefabricated Operation Theatre

Price 105000 INR/ Unit

Prefabricated Operation Theatre Specification

- Wall Materials

- Jointless PUF panel, GI pre-coated/SS laminated finish

- Connection

- Modular interlocking system

- Door Material

- Powder-coated galvanized steel, Hermetically sealing

- Insulation

- Polyurethane foam (PUF) core, high thermal efficiency

- Dimension (L*W*H)

- 6m x 4m x 3m (custom sizes available)

- Life Span

- 20+ years with proper maintenance

- Window Material

- Double-glazed glass, Aluminum/UPVC frame

- Open Style

- Sliding (automatic/manual)

- Material

- Modular prefabricated panels (PUF core, GI/Aluminum outer)

- Roof Material

- Insulated PUF panels with GI/Aluminum sheet top layer

- Door

- Single/double leaf, hermetically sealed

- Thickness Of Wall Panel

- 50 mm - 100 mm

- Window

- Observation, double-glazed transparent

- Window Style

- Fixed, optional with Venetian blinds

- Floor Material

- Epoxy seamless antistatic flooring

- Floor Load

- Suitable for heavy equipment, approx. 350 kg/m

- Roof Dead Load

- 25 kg/m

- Roof Live Load

- 100 kg/m

- Earthquake Intensity

- Designed up to Zone 4 seismic standards

- Color

- White, customizable options

- Use

- Hospital, Surgical procedures

- Ceiling Material

- High-grade SS/Aluminum GI, smooth, antistatic finish

- Fire Resistance

- Fire-retardant panels, Class 1

- Electrical Supply

- Medical-grade wiring, backup circuit with UPS

- Air Filtration

- HEPA 0.3 micron, 99.97% efficiency

- Compliance

- NABH, HTM 2025, ISO 14644 standards

- Medical Gas Outlets

- O2, N2O, vacuum, compressed air integrated

- Antibacterial Coating

- Walls and floor with antimicrobial finish

- Cleanliness Class

- ISO Class 7/8

- Humidity Control

- RH 45-60% auto-controls

- Mobility

- Relocatable modular units

- Lighting

- Shadowless, LED ceiling-mounted OT light

- Sterilization System

- Provision for UV, fumigation ports

- Pass Box

- SS pass box with interlocking system

- Installation Time

- 7-15 days (site conditions dependent)

- Pressure Differential

- Maintained at +15 Pa in sterile area

- Temperature Control

- Integrated HVAC modular AC

- Ventilation System

- Laminar Air Flow with pre-filters & terminal HEPA units

Prefabricated Operation Theatre Trade Information

- Minimum Order Quantity

- 50 Square Meters

- Supply Ability

- 15 Square Meters Per Day

- Delivery Time

- 15 Days

About Prefabricated Operation Theatre

We are engaged in providing a wide area of Prefabricated Operation Theatre. It is available in different specifications and requirements as per the needs of the clients. This theatre is ideal for the purpose due to their unmatched quality traits. It is specially developed by deft professionals and premium tools. Prefabricated Operation Theatre is to keep the air clean of fungus and dust particles. It ensures for the improvement of Hospital areas and also aid to reduce the risk of infections.

Specification

| External static pressure | 75Pa |

| High-efficiency | 70% |

| Material | SS |

| Brand | Kaizen |

| Built Type | Modular |

| Usage/Application | Hospital |

Advanced Infection Control

Equipped with HEPA filters, laminar air flow, and antimicrobial coatings on floors and walls, this theatre maintains ISO Class 7/8 cleanliness. The environment minimizes particulate contamination and supports high-level air purity, essential for critical surgical procedures.

Superior Structural Integrity and Safety

The operation theatre is constructed using insulated PUF panels with earthquake and fire-resistance features. Sliding hermetically-sealed doors, double-glazed observation windows, and a seamless epoxy antistatic floor provide robust durability and patient safety, even in highly demanding conditions.

Efficient Installation and Mobility

Designed for rapid deployment, the modular units can be installed within 7-15 days depending on site conditions. The system's relocatable panels and modular connections enable quick setup or transfer, delivering flexibility for hospitals seeking upgraded or temporary surgical spaces.

FAQ's of Prefabricated Operation Theatre:

Q: How is the prefabricated Operation Theatre installed and how long does it take?

A: Installation is modular and typically completed within 7 to 15 days, subject to site conditions. The theatre's interlocking PUF panels enable rapid assembly and integration, minimizing downtime for hospital facilities.Q: What air quality and cleanliness standards does this Operation Theatre meet?

A: It maintains ISO Class 7/8 cleanliness with HEPA filtration (0.3 micron, 99.97% efficiency), laminar airflow, and antibacterial wall and floor coatings. These features ensure an optimal sterile environment for advanced surgical procedures.Q: Where can this modular Operation Theatre be used?

A: This theatre is suitable for hospitals, clinics, and specialty surgical centers. Its flexible, relocatable design makes it ideal for both permanent installations and temporary or expanding medical facilities.Q: What electrical and safety provisions are integrated into the theatre?

A: The system uses medical-grade wiring with backup UPS circuits. Fire-retardant Class 1 panels, seismic resistance up to Zone 4, and automatic humidity (RH 45-60%) and temperature controls enhance overall safety and operational reliability.Q: How is air sterilization managed within the theatre?

A: Air is sterilized using terminal HEPA units, UV sterilization provision, and fumigation ports, maintaining a +15 Pa pressure differential in the sterile area to prevent contamination during procedures.Q: What are the main benefits of using this prefabricated Operation Theatre?

A: Benefits include rapid installation, consistent sterility, robust structural safety, customizable configuration, compliance with NABH, HTM 2025, and ISO 14644, and long lifespan exceeding 20 years with proper maintenance.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Modular Operation Theatre Category

Laminar Flow Operating Theatre

Price 125000 INR / Unit

Minimum Order Quantity : 50 Square Meters

Open Style : Other, Sliding / Hinged

Earthquake Intensity : Seismic Resistance up to Zone IV

Door : Other, Hermetically Sealed Auto / Manual Doors

Door Material : Other, Powder Coated Steel or SS Door

Kaizen Modular Operation Theatre

Price 145000.00 INR / Unit

Minimum Order Quantity : 50 Square Meters

Open Style : Sliding

Earthquake Intensity : Up to Zone 4 withstand capability

Door : Other, Automatic sliding / swing doors

Door Material : Other, Hermetically sealed stainless steel or powder coated GI

Send Inquiry

Send Inquiry

English

English Spanish

Spanish French

French German

German Italian

Italian Chinese (Simplified)

Chinese (Simplified) Japanese

Japanese Korean

Korean Arabic

Arabic Portuguese

Portuguese